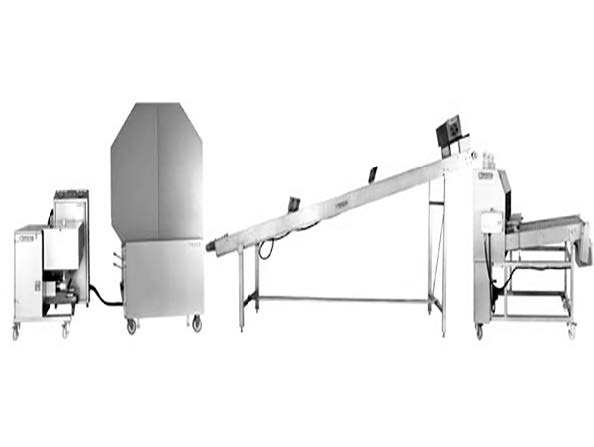

INP-520 Semi-Auto Spring Roll Making Machine

September 11, 2020

INP-540 Chinese Meat Bun – Sweet Bun Forming Machine

September 11, 2020INP-530 Twin Baked Drum Pastry Sheet Making Machine

INP-530 double-roasted spring roll wrapping machine to provide high-volume spring roll wraps to meet customer demand. The INP-530 is the doubled yield of the INP-510, Available in a maximum range of 23-25 cm. Compared to the INP-510, the HM-660 is a space-saving, labour-saving, low-maintenance, low-power consumption model that significantly reduces the time it takes to clean machine parts .

INP-530 is equipped with double grilled wheels, ice machine, spring roll cooling system, skinning counting stack system and finished conveyor belt. In a nutshell it will bake, cool, cut, count, and stack the system in one place.

In the grilled wheel parts, grilled wheels are special materials, durable for more than 20 years. The outer circumference of the baking wheel is provided with a thermal insulation

cover, and the heat resistant wire can reach 480℃ The baking temperature of the baking wheel can be adjusted according to the formula and thickness of the skin. According to the order requirements, the use of unilateral baking round of production.In the peel count stacking system, the hardness of the cutter is hard, if the wear can be adjusted, do not have to replace the cutter immediately. And can be arbitrarily set according to customer needs, up to 99 as a stack. With a white iron conveyor belt network, more in line with international health needs.

Specification:

。Capacity:5,400 pcs/hr

。Dimension:6,800mm(L)x 1,420mm(W)x 1,900mm(H)

。Electricity:3Phase, 220V, 56kw

Food Produced by this machine:

SPRING ROLL

PASTRY SHEET

Reviews

There are no reviews yet.